A leader in many niche industries worldwide

We use our technical capabilities in polymer science to solve challenges for our customers.

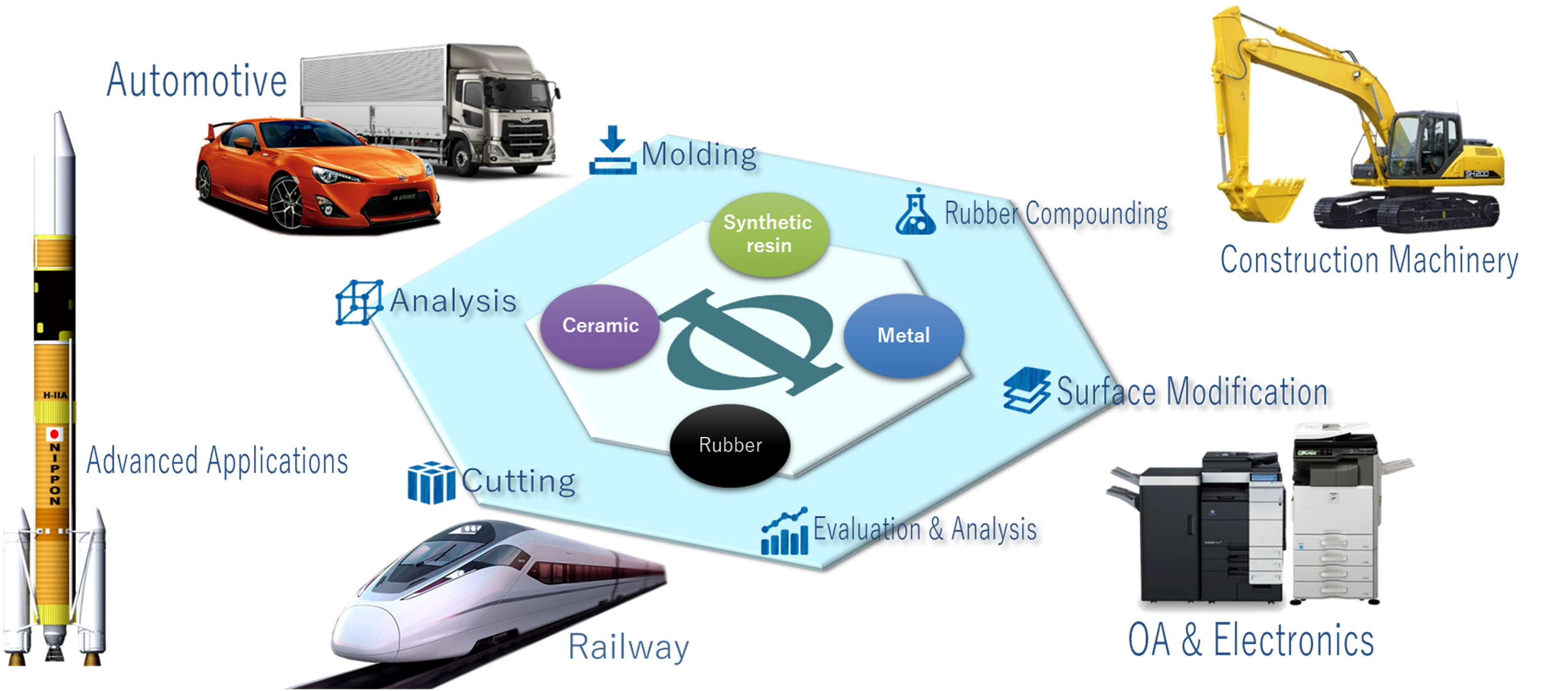

Our Business Scope

Our knowledge and expertise extend beyond rubber to several other commercial technologies. Our various rubber products have applications across a wide range of fields.

The Meaning of “Fukoku”

When the founder of Fukoku, Mr. Eiichi Kawamoto, established our company in 1953, he wanted to contribute to making the country of Japan more “abound”, meaning “abundant or plentiful.” Following from this, “Fukoku” means “abound country.” We incorporated “Fukoku” into the company name and established Fukoku Rubber Industry close to Tokyo in Japan. When we changed the company name in January 1986, we went with the name “Fukoku” to continue contributing to global “abound-ness” by expanding our business and values with our associates at Fukoku Group.

Yes, We Do!

The issue-solving capabilities to stand by our customer’s side to face their problems

Our Corporate Spirit of “Yes, We Do!” expresses how we approach the various requests and challenge of our customers with the willingness to try things out. This spirit is deeply rooted in Fukoku’s culture. With our integrated system covering everything from material review to design, assembly, and commercialization, one of our strengths is the ability to respond flexibly and quickly, even to customized requests.

Development capabilities applying rubber raw material compounding, bonding, surface modification, and molding technologies

Fukoku’s fundamental technology as a company lies in polymer raw materials, particularly rubber raw materials.

We also have diverse peripheral technologies.

We are engaged in material development, configuration design, mold processing, and a variety of other fields.

For example, we can handle the composite design of rubber, metal, resin, liquid, and other materials to aggressively develop new products that meet our customers’ needs.

Other ways we’re the best in the world:

Many Fukoku products boast the top global share.

Fukoku boasts the No. 1 production volume of wiper blade rubbers worldwide as well as high global shares in other products. For example, take our viscous mounts for hydraulic excavators (70% global share), wiper blade rubbers (50%), valves for evaporation-purge devices (35%), immunotherapeutic closed-type culture bags (35%), brake booster diaphragms (30%), or wire saw urethane rollers for semiconductor silicon wafer production (30%).

Our excellent product quality, superior technologies, and stable supply system demonstrate how we can make so many products that continue to be supported by many customers around the world.